Prototyping

Ensure confidentiality and speed-to-market with prototypes of the highest standards.

From concept

to reality

At Nottingham Spirk, prototyping isn’t just about fabrication — it’s about innovation in action. Our team of engineers, machinists, artists, and technicians play an integral role in transforming bold ideas into tangible, functional prototypes that bridge the gap between concept and commercialization.

From the earliest sculptural models that inform design decisions to fully functional prototypes that look, feel, and operate like the final product, our in-house experts accelerate development by integrating seamlessly with discovery, validation, and engineering teams. With a vast range of cutting-edge tools and hands-on expertise, we craft high-quality prototypes that allow clients to experience and refine their products before manufacturing even begins.

Capabilities at

a glance

/01

Precision machine & metalwork

From high-precision CNC milling and 5-axis routing to traditional lathes and manual milling, our machining capabilities allow us to create complex, production-grade components with exceptional accuracy. Whether fabricating intricate prototypes or refining engineering specifications, our machining team ensures that each part meets real-world tolerances and functional requirements.

/02

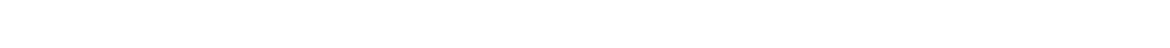

Advanced metal fabrication & welding

Our in-house TIG and stick welding, plasma cutting, and sheet metal forming capabilities allow us to prototype structural and functional metal components with durability in mind. From robust framework designs to intricate assemblies, we ensure that every weld and bend meets the rigorous demands of real-world applications.

/03

Molding & casting for rapid iteration

With injection molding, polymer casting, and silicone molding, we rapidly create high-fidelity parts that mimic production materials and performance. This enables fast-turnaround iterations, allowing teams to test form, function, and manufacturability before committing to costly production tooling.

/04

Textile & soft goods development

Using heavy-duty sewing machines, laser cutting, and RF welding, we develop fabric-based components for wearables, soft goods, and flexible product applications. Whether creating ergonomic straps, waterproof enclosures, or heat-sealed protective materials, our textile capabilities bring soft materials into the prototyping process with precision and durability.

/05

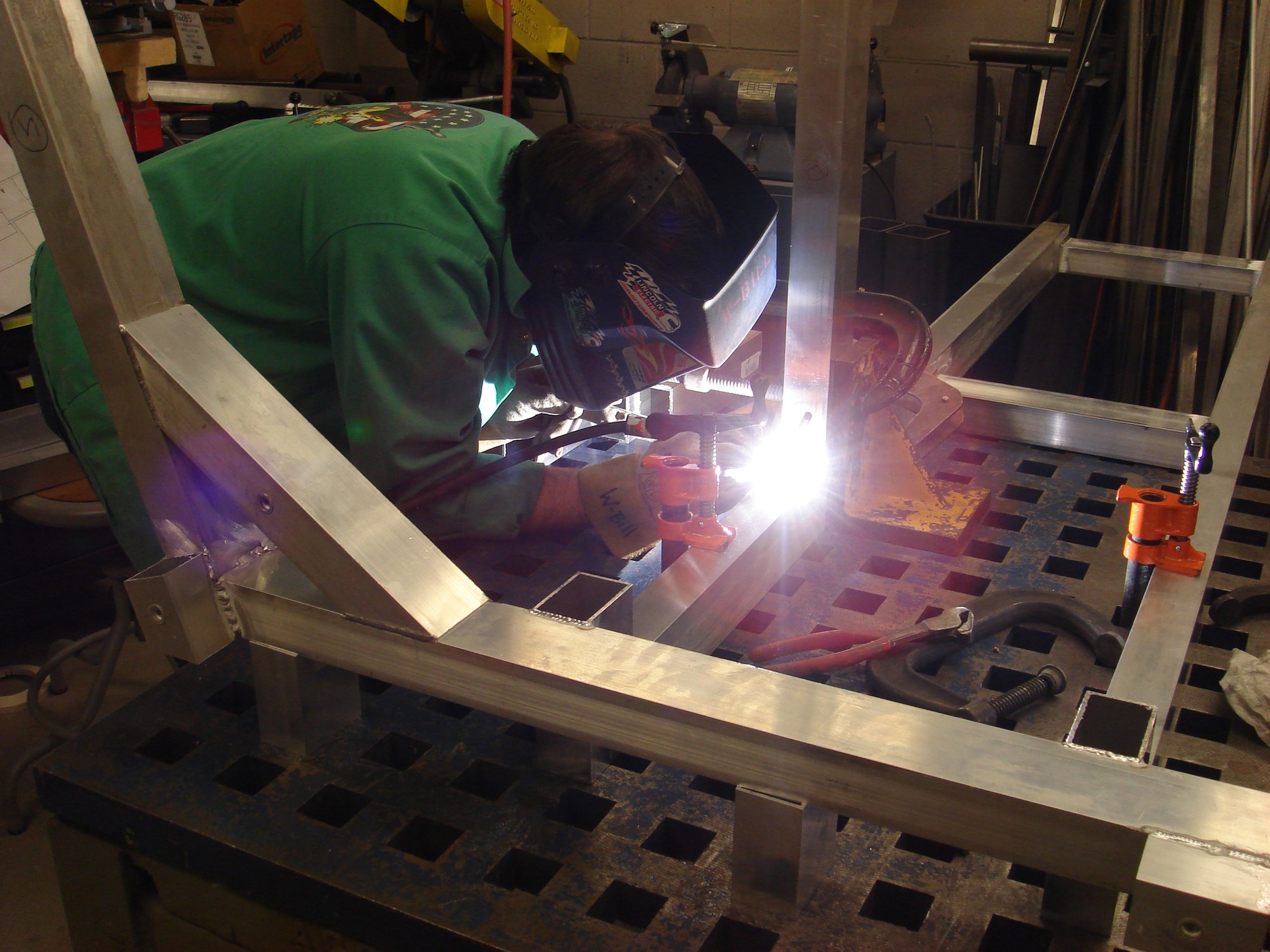

3D printing for rapid prototyping

Our large-format FDM and SLA 3D printers enable fast, cost-effective prototyping with a high level of detail and structural integrity. These tools allow us to iterate quickly, producing parts that can be tested for mechanical fit, function, and even end-use applications.

/06

Thermoforming & vacuum forming

With small- and large-scale vacuum forming machines, we produce lightweight, durable plastic components that can be used for casings, enclosures, and packaging prototypes. This capability allows us to simulate real-world manufacturing processes while maintaining agility in early-stage product development.

/07

Automotive-grade paint & finishing

A fully functional prototype isn’t complete without a production-level finish. Our automotive paint booths and color-matching system ensure that prototypes not only work as intended but also look and feel like the final product. Whether applying a custom color scheme or high-durability coatings, our finishing team helps bring product visions to life.

/08

Wood & foam fabrication for structural prototyping

Using precision saws, lathes, routers, and sanders, we craft foam and wooden models to explore form, ergonomics, and structural integrity. Whether creating early-stage volume studies or high-detail, finished prototypes, these techniques allow for rapid iteration before committing to full-scale production materials.

.png)

Innovation you

can hold

With a dedicated facility housing state-of-the-art equipment, we don’t just build prototypes — we build confidence in what comes next. By integrating prototyping into every stage of development, Nottingham Spirk ensures that ideas don’t just stay on paper — they take shape, evolve, and become reality.

Our Work

Consumer Products

HALO Bassinest®

Bassinet that swivels to provide a safe and easy co-sleeping experience.

Consumer Products

Matco RevelX Automotive Toolbox

Reimagined modular toolbox system with tech integration.